What is PLC?

What is a Programming Logic Controller (PLC)?

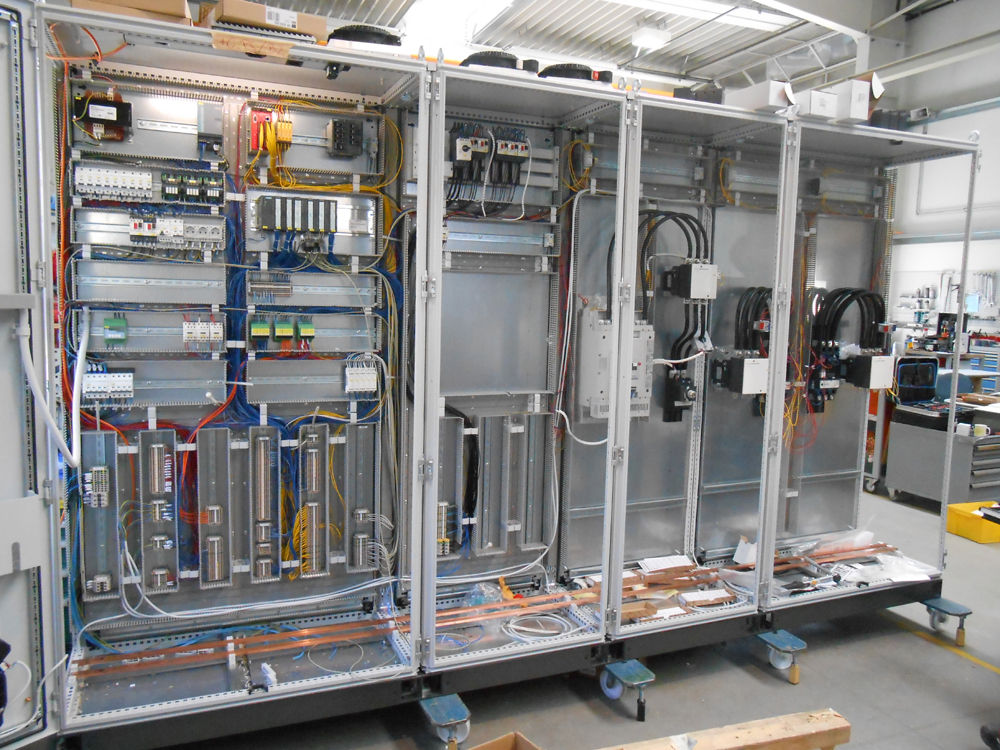

Programmable Logic Controllers (PLCs) also referred to as programmable controllers, are in the computer family. They are used in commercial and industrial applications.

A PLC monitors inputs makes decisions based on its program and controls outputs to automate a process or machine.

An industrial digital computer that is roughened and optimized for manufacturing process control such as assembling lines, robot equipment or other procedures including high precision, quickly programmed and process failure diagnostics is a programmable logic controller (PLC) or programmable controllers.

PLCs can be from modular small devices with hundreds of I / O processor integrated housing and large modular rack-mounted devices counting thousands of I / O devices, mostly networked to other PLC and SCADA systems. PLCs can be based on smaller modular systems. They can be equipped for various digital and analogue I / O arrangements, extended temperature ranges and electrical immunity.

LC Programming for Solutions of Community

- Automotive

- Cement

- Chemical

- Food & Beverage

- Glass

- Machine Tools

- Marine

- MES

What is a programmable controller?

A programmable controller is a microprocessor-based industrial controller the functions of which are determined by a stored program.

What is a program?

A program is a set of instructions telling the controller how to behave. It is stored in the controller's memory.

How does a programmable controller differ from a computer?

Computer is optimized for calculation and display tasks and is programmed by specialists. A programmable controller is optimized for control and regulation tasks and can be programmed by non-specialists. It is also well adapted to the industrial environment. A Common Example of Regulation Task is Traffic Signals.

What is PLC programming and why it is important?

PLC programming creates a programmable logic control (PLC) internal logic. PLCs typically come in a "language" owned by a controller which is precisely designated as a translation from a word spoken to something that can be read and performed by a controller ("If condition 1 is true, and condition 3 is false, turn on output 12") to something the controller can interpret and execute (“If I1.0 = 1 and I1.2 = 0 then O12.0 = 1”).

Why are programmable controllers so common?

Because they are cost-effective and have significant advantages over traditional control systems based on relays or pneumatics.

Where are they used?

In virtually every industry where automation is involved, from individual machines to whole processes, in commercial, institutional and industrial premises.

What are the main advantages?

A control system based on a programmable controller is flexible, reliable and compact and can be assembled at a relatively low cost.

Are all programmable controllers the same?

They are broadly similar in a functional sense but they differ in size, programming detail and mechanical design. Most manufacturers offer several models with different levels of performance.

What tasks does a programmable controller perform?

The control tasks previously undertaken with electrical and/or pneumatic controls, e.g. interlocking, sequencing, timing and counting. It can, in addition, perform a variety of tasks.

Does a programmable controller eliminate contactors and valves?

No, but these items are brought under the programmable controller's influence in modern control systems.

What is a Basic PLC Operation?

- PLCs consist of input modules or points, a Central Processing Unit (CPU) and output modules or points. (Refer to Figure)

- An input accepts a variety of digital or analogue signals from various field devices (sensors) and converts them into a logic signal that can be used by the CPU.

- The CPU makes decisions and executes control instructions based on program instructions in memory.

- Output modules convert control instructions from the CPU into a digital or analogue signal that can be used to control various field devices (actuators).

- A programming device is used to input the desired instructions.

- These instructions determine what the PLC will do for a specific input.

- An operator interface device allows process information to be displayed and new control parameters to be entered.

Advantages of PLC

- The same (WLC) as well as more complex tasks, can be done with a PLC.

- Wiring between devices and relay contacts is done in the PLC program.

- Hard-wiring, though still required to connect field devices, is less intensive.

- Modifying the application and correcting errors are easier to handle.

- It is easier to create and change a program in a PLC than it is to wire and rewire a circuit.

- Smaller physical size than hard-wire solutions.

- Easier and faster to make changes.

- PLCs have integrated diagnostics and override functions.

- Diagnostics are centrally available.

- Applications can be immediately documented.

- Applications can be duplicated faster and less expensively.

Applications of programmable logic control

- Automobile Industries

- Plastic Industries

- Heavy Industries

- Chemical Industries

- Food & Beverages Industries

- Machinery's

- Building Services

- Transport Systems

- Energy, Gas, Water & Air

- Textile Industries

AC/DC drive control, temperature control, heating/drying control, spinning, dyeing and color mixing.

Knowledge Level For PLC Programming

- A person knowledgeable in relay logic systems can master the major PLC function in a few hours.

- These functions might include coils, contacts, timers and counters.

- The same is true for a person with knowledge of digital principles, however, the learning process takes more time.

Remember: A relay is digital in nature because it is basically an on/off two-state device.