What is PCB?

What is a PCB?

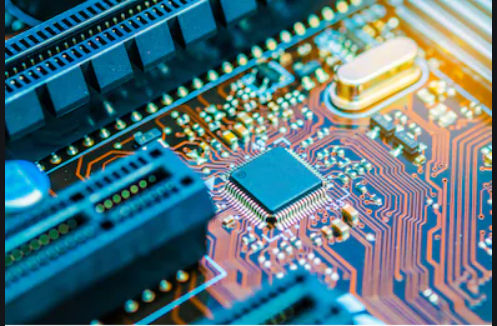

PCB physically supports and electrically links electrical or electronic components using conductive loops, pads and other features etched from one or more layers of copper laminated on and/or within sheet layers of a non-conductive substrate. Components are usually soldered to the PCB to be electrically bound and physically linked to the PCB.

Printed circuit boards are used with anything but the smallest computer goods. These are often found with other electronic devices such as passive control boxes.

As you already know printed circuit boards are very popular in the field of electronics and you 're probably going to find one in the devices you use every day. Nevertheless, these technological gadgets are still utilized by individuals without knowing or recognizing the technologies behind them. Here are the fundamentals of PCB architecture, modules and installation to offer you a better understanding of how your electronic devices function.

In its simplest form, a PCB is a plastic board reinforced with glass. Attached to this board are copper lines and pads which connect, cut from a copper layer. These copper lines (known as traces) allow electrical charge to flow through the PCB, providing power to the different components that are situated systematically on the board. The copper traces function in the place of wires, guiding the electricity to the correct destination.

Components on a PCB

If the copper traces serve as the backbone of the PCB, serving as its essential framework, then the components are the critical organs. Each of them has a different function. They give the circuit unique qualities that make it fit to its intended purpose. Depending on the device or electronic item for which the PCB is designed, different components will be needed for different circuits. Such components can consist of a broad range of electronic components. Several rising components of PCBs include:

Battery: Provides voltage to the circuit.

Resistors: Control the electrical current as it passes through them. They’re color-coded to determine their value.

LEDs: A light-emitting diode. Lights up when current flows through it and will only allow current to flow in one direction.

Transistor: Amplifies charge.

Capacitors: These are components which can harbor electrical charge.

Inductor: Stores charge and stop changes in current.

Diode: Allows current to pass in one direction only, blocking the other.

Switches: Can either allow current or block depending if they are closed or open.

Different Types of PCBs

PCBs have copper tracks to connect the holes where various components are located, they are specially designed for each circuit and build construction is very easy. The different types of printed circuit boards mainly include the following:

- Single-Sided PCBs

- Double-Sided PCBs

- Multilayer PCBs

- Rigid PCBs

- Flex PCBs

- Rigid-Flex PCBs

Single-Sided PCBs

The single-sided printed circuit board comprises just one sheet of base material or substrate. One end of the base is covered with a thin metal sheet, typically copper, since it is a strong electrical conductor. Typically a safe welding mask is positioned at the top of the copper sheet and the last silkscreen coat can be added to the surface to label the elements of the plate.

Double-Sided PCBs

This form of PCB is far more common than single-sided boards. The two sides of the base of the board have metal conductive pads and the components are fixed on both ends. Holes in the PCB require circuits on one side to be connected to circuits on the other side.

Multilayer PCBs

These PCBs further increase the density and complexity of PCB designs by adding extra layers beyond the upper and lower layers seen in a double-sided configuration. With the flexibility of multi-layer printed circuit board configurations across multiple layers, multilayer PCBs enable designers to create very dense and highly composite designs.

Rigid-Flex PCBs

Rigid-flex boards incorporate the features with both flexible and rigid circuit boards. A simple rigid-flex board consists of a rigid circuit board that is connected to a flex circuit board. Such boards can be more specific if design proposals are sought.

Compact Size and Saving of Wire

The PCB contains a wide variety of electronic parts. On a printed circuit board, the interconnection between the modules is rendered by way of copper tracks instead of having a variety of current conveying wires. It makes the ties less bulky. Both components are low in number. Without the aid of printed circuit boards, it would be almost difficult to link such components together with wires. A printed circuit board provides a basic medium for assembling electronic components compactly and effectively. This compactness enables the development of large and complicated electronic circuits in limited form factors. This in turn takes less space in devices.

Ease of Repair and Diagnostic

If there is some harm, it is very easy to test and repair the specific failure components. The electronic components and their polarities on a correctly built printed circuit board are identified on the wall. This requires flexibility during the construction process as well as during the repair process. Signal channels are also tracked during treatment.

Time-Saving

The modern system of circuit connections requires a lot of time to link the components. Whereas the digital circuit board requires less time to build the circuit than the traditional process.

Immune to Movement

The most critical aspect to remember is that all the components on the printed circuit board kept fastened to the frame. This is achieved by the solder flux which does not enable them to travel independently of the movement of the board itself.

Tight connections and Short Circuits Avoided

As the connections are made automatically through copper tracks, there is no chance of loose connections or short circuits.

Low Electronic Noise

The printed circuit board (which has been professionally designed) provides less electrical noise. If it is not properly constructed, the noise may greatly degrade the output of the circuit. The electrical components on the printed circuit board are arranged in such a manner that the length of the electrical current between them is as low as practicable. This leads to low contamination and pick-up of electromagnetic waves, while providing a lower crosstalk between and from modules, which is typically a big concern in electronic circuits. Electrical activity may be emitted in the form of flame, radiation, or flickering.

Low Cost Mass production can be achieved at a lower cost.

Reliability

All the above factors bring reliability in the performance of the circuit.