What is a Closed Cycle Gas Turbine & Its Working

What is a Closed Cycle Gas Turbine & Its Working

A closed-cycle gas turbine design is used to address the drawbacks of the open-cycle gas turbine method. Corrosion of turbine blades is the key downside of an open cycle. This downside can be resolved by using the superior nature of the operating medium (air or helium, argon, hydrogen or neon) where it is not combined with the fuel in the combustion chamber. The other drawback of using a closed-cycle system is that the heat of the exhaust gases is rejected by the re-cooler or by the re-cooler.

Difference between closed and open cycle Gas Turbine

The basic difference between them is the circulation of the working fluid. In the closed cycle gas turbine the same working fluid is circulated again and again within the turbine but in the open cycle gas turbine the working fluid i.e. air is replaced again and again while flowing through the gas turbine.

What is a Closed-cycle Gas Turbine?

A closed-cycle gas turbine can be defined as a gas turbine, which overcomes the drawbacks of the open cycle gas turbine. In this type of turbine, the air is circulated continuously within the gas turbine with the help of a compressor, heat chamber, gas turbine, and cooling chamber. The ratios of pressure, temperature and air velocities will be constant in this type. It performs a thermodynamic cycle, which means working fluid is circulated and used continuously again and again without leaving the system.

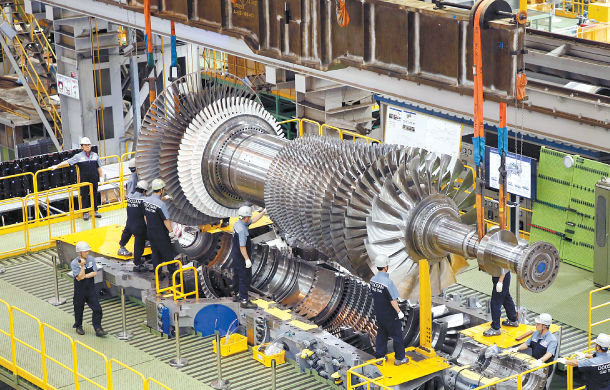

A closed-cycle gas turbine diagram is very simple and contains components like a compressor, heat chamber, and a gas turbine. The generator, compressor, and cooling chamber are driven by the gas turbine. The diagram of this is shown below.

- The gas is compressed in the compressor.

- The compressed gas is heated in the heating chamber.

- The gas turbine helps to generate electricity.

- Electricity is generated by the generator with the use of gas turbine

- The cooling of gases passed from the turbine gets cooled in the cooling chamber.

Closed Cycle Gas Turbine Working Principle

The closed-cycle gas turbine working principle is based on the Brayton cycle or Joule’s cycle.

In this type of gas turbine, the compressor is used to compress the gas isotropically and the resultant compressed gas flows into the heating chamber. The rotor type compressor is preferred in this turbine.

An external source is utilized to heat the compressed air and then passed over the turbine blades.

When the gas is flowing over the turbine blades, it gets expanded and it is allowed to pass into the cooling chamber and gets cooled down. The gas gets cooled by using the circulation of water at constant pressure to its initial temperature.

- Again the gas is passed into the compressor and the process is repeated.

- In this turbine, the same gas is circulated repeatedly.

- The complexity of the system and the cost would increase if the working fluid/medium used in the turbine is other than air. This may lead to problems and it is difficult to resolve.

Advantages

The closed-cycle gas turbine advantages are

- High thermal efficiency at any temperature limit and pressure ratio

- Any type of working fluid can be used with low caloric value. For example helium.

- No corrosion.

- Internal cleaning is not required.

- Re-heaters can be used to heat the water for the supply of hot water for domestic and industrial purposes.

- The size of the gas turbine is small

- An increase in pressure gives a better heat transmission coefficient in the exchanger

- Fluid friction loss is less.

Disadvantages

The closed-cycle gas turbine disadvantages are

- As the whole system works under high pressure with a working fluid (medium), it increases the cost.

- It requires a large air heater and it is not enough when the combustion chamber is used in the open cycle.

- Not used in aeronautical engines because this type of gas turbine uses cooling water.

- Complex system and should resist at high pressure.

Applications

The closed-cycle gas turbine applications include the following

- Used in the generation of electric power

- Used in many industrial applications

- Used in marine propulsion, locomotive propulsion, automotive propulsion

- Used in aviation to provide power to the jet propulsion