PID Controller : Working & Applications

PID Controller : Working & Applications

As the name suggests, this blog will provide a precise idea of the configuration and function of the PID controller. However, let's have an introduction to the PID controllers. PID controllers are used in a broad variety of industrial process control systems. Approximately 95 per cent of closed-loop processes in the industrial automation industry use PID controllers. An essential element of more sophisticated controllers PID stands for Proportional-Integral-Derivative. These three controllers are coupled to create a control signal. As a feedback controller, it provides power output at the desired level. Before the microprocessors were invented, the control of the PID was carried out by analogue electronic components. But today, all PID controllers are being processed by microprocessors. Programmable logic controllers also provide instructions for the built-in PID controller.

What is a PID Controller?

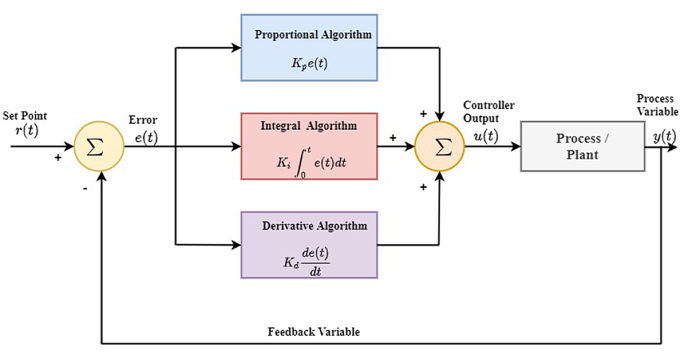

A proportional–integral–derivative controller (PID controller or three-term controller) is a control loop device that uses feedback that is commonly used in industrial control systems and a number of other applications involving continuously modulated control. The PID controller continuously measures the error value e(t) as the difference between the desired setpoint (SP) and the calculated process variable (PV) and applies a correction dependent on the proportional, integral and derivative terms (denoted P, I, and D respectively), hence the name.

PID Controller Example

A good example of a PID temperature control will be an application where the controller takes an input from a temperature sensor and has an output that is attached to a control element such as a heater or a fan.

Working of PID Controller

With the use of a low cost simple ON-OFF controller, only two control states are possible, like fully ON or fully OFF. It is used for a limited control application where these two control states are enough for the control objective. However the oscillating nature of this control limits its usage and hence it is being replaced by PID controllers.

PID controller maintains the output such that there is zero error between the process variable and setpoint/ desired output by closed-loop operations. PID uses three basic control behaviors that are explained below.

P- Controller

Proportional or P- controller gives an output that is proportional to current error e(t). It compares the desired or set point with the actual value or feedback process value. The resulting error is multiplied with a proportional constant to get the output. If the error value is zero, then this controller output is zero.

This controller requires biasing or manual reset when used alone. This is because it never reaches the steady-state condition. It provides stable operation but always maintains the steady-state error. The speed of the response is increased when the proportional constant Kc increases.

I-Controller

Due to the limitation of a p-controller where there always exists an offset between the process variable and setpoint, an I-controller is needed, which provides necessary action to eliminate the steady-state error. It integrates the error over a period of time until the error value reaches zero. It holds the value to the final control device at which error becomes zero.

Integral control decreases its output when a negative error takes place. It limits the speed of response and affects the stability of the system. The speed of the response is increased by decreasing integral gain, Ki.

In the above figure, as the gain of the I-controller decreases, the steady-state error also goes on decreasing. For most of the cases, the PI controller is used particularly where the high-speed response is not required.

While using the PI controller, I-controller output is limited to somewhat range to overcome the integral wind up conditions where the integral output goes on increasing even at zero error state, due to nonlinearities in the plant.

D-Controller

The I-controller doesn’t have the capability to predict the future behavior of error. So it reacts normally once the setpoint is changed. D-controller overcomes this problem by anticipating the future behavior of the error. Its output depends on the rate of change of error with respect to time, multiplied by derivative constant. It gives the kick start for the output thereby increasing system response.

In the above figure response of D, the controller is more, compared to the PI controller, and also settling time of output is decreased. It improves the stability of the system by compensating for phase lag caused by the I-controller. Increasing the derivative gain increases the speed of response.

So finally we observed that by combining these three controllers, we can get the desired response for the system. Different manufacturers design different PID algorithms.

Types of PID Controller

PID controllers are classified into three types like ON/OFF, proportional, and standard type controllers. These controllers are used based on the control system, the user can use the controller to regulate the method.

ON/OFF Control

An on-off control method is the simplest type of device used for temperature control. The device output may be ON/OFF through no center state. This controller will turn ON the output simply once the temperature crosses the fixed point. A limit controller is one particular kind of ON/OFF controller that uses a latching relay. This relay is reset manually and used to turn off a method once a certain temperature is attained.

Proportional Control

This kind of controller is designed to remove the cycling which is connected through ON/OFF control. This PID controller will reduce the normal power which is supplied toward the heater once the temperature reaches the fixed point.

This controller has one feature to control the heater so that it will not exceed the fixed point however it will reach the fixed point to maintain a steady temperature. This proportioning act can be achieved through switching ON & OFF the output for small time periods. This time proportioning will change the ratio from ON time to OFF time for controlling the temperature.

PID controller Transfer Function