What is an ultrasonic motor?

Ultrasonic Motors

What is an ultrasonic motor?

An ultrasonic motor rotates a rotor by using ultrasonic waves with high frequencies more than 20,000Hz which a human cannot hear. The ultrasonic motor generates ultrasonic waves using piezoelectric elements, while conventional motors use permanent magnets or coils to rotate a rotor.

The piezoelectric element swells and contracts depending upon a difference of electric potential between two terminals, and this frequent swelling and contracting generate the ultrasonic waves.

Working of the Ultrasonic Motors

The vibration is induced into the stator of the motor, and it is used for conveying the motion to the rotor and to modulate the frictional forces. The amplification and (micro) deformations of active material are utilized for generation of the mechanical motion. The macro-motion of the rotor can be achieved by the rectification of the micro-motion using the frictional interface between the stator and the rotor.

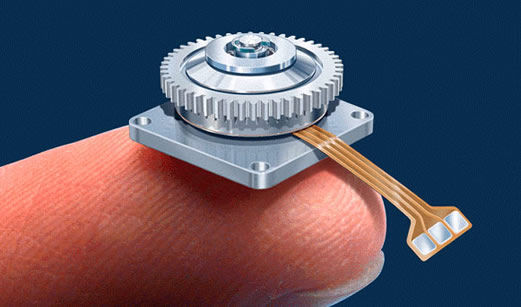

Structure of Ultrasonic Motor

Ultrasonic motor: The main structures of the USR series are the following

- The Stator part transmits vibration

- The Rotor which is a rotation part

- The Shaft which transmits rotation

- The Bearing

Furthermore, the structure of a stator part is the following.

- The Piezo-Electric Ceramics which generate vibration

- The Stator metal which makes vibration amplify

- The Friction material which contacts with a rotor

Advantages of Ultrasonic Motors

- These are small and are excellent in response.

- These have low speed of ten to several hundred rpm and high torque, and hence reduction gears are not required.

- These consist of high-holding power, and even if the power is turned off, they do not need a brake and clutch.

- They are small, thin and have less weight compared to other electromagnetic motors.

- These motors do not contain any electromagnetic material and they do not generate electromagnetic waves. So, these can be used even in high magnetic field areas as these are unaffected by the magnetic field.

Disadvantages of Ultrasonic Motors

- A high-frequency power supply is required.

- As these motors operate on friction, durability is very less.

- These motors have drooping speed-torque characteristics.

Applications of Ultrasonic Motors

- Used for the autofocus of a camera lens.

- Used in compact paper handling devices and watches.

- Used in conveying machine parts.

- Used for drying and ultrasonic cleaning.

- Used to inject oil into the burners.

- Used as the best motors known to offer high potential for miniaturization of equipment.

- Used in MRI magnetic resonance imaging scanning in medicine.